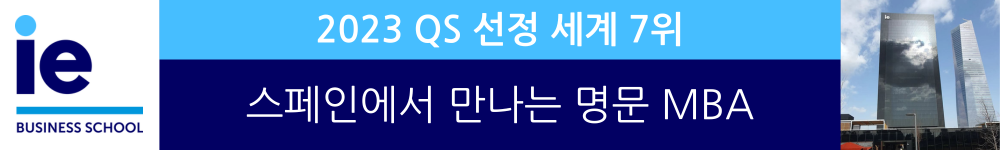

What originally inspired you to leave Austria and build your entrepreneurial journey in Korea?

I wrote my first lines of code at the age of 12 in Vienna and spent the next 17 years building ERP and CRM systems across Europe. In 2013, I relocated to South Korea to open a branch office. Very quickly I realized this country had something unique: incredible consumer standards, a world-class design culture, and the speed that forces you to innovate or fail. For me, Korea became not just a new home but the ultimate testbed. If you can digitize packaging in Korea, one of the most competitive markets in Asia, you can scale it anywhere in the world.

How has your personal background in ERP and workflow systems influenced the way you designed Packative?

I spent almost two decades working with B2B enterprise software clients. In the early days I had little guidance and had to figure out project management, customer communication, and delivery on my own. That experience shaped everything about Packative. I knew from the start that packaging was not just a printing problem, it was a workflow and business process problem. I developed the first version of the platform entirely myself, from the ecommerce frontend to the backend ERP to the pricing engine and 3D design tools. By embedding ERP automation and workflow logic into the core, we transformed packaging into a real-time software challenge where design, pricing, and production flow seamlessly together.

What leadership principles guide you in scaling a company from idea to millions of produced packages?

For me, leadership comes down to three principles: Proactive Ownership, Radical Clarity, and Humility with Self-Awareness. I believe in giving people real ownership, because that is how they grow and take responsibility. I believe in radical clarity—being direct and straightforward, although I admit this can sometimes be a challenge when navigating cultural differences. And I believe humility and self-awareness are essential for any founder, because without them you cannot learn, adapt, or build trust. Combined, these principles create a culture where execution naturally follows and outcomes are achieved.

What problem in the packaging industry motivated you to found Packative?

In 2018 I worked as a local partner for the Olympic Games, helping twelve country houses set up in Korea. We handled everything from building websites to printing logos on cars, managing supply chains and assets, and even importing containers of cheese and mustard. The only project we failed to achieve was packaging. That experience opened my eyes. Traditional suppliers required high minimums, worked entirely offline, and relied on slow RFQ processes that made it almost impossible for smaller projects or new brands to succeed. Packaging was one of the least digitized industries I had ever seen. Packative was born to solve this by making packaging instant, accessible, and scalable. And because quality matters, every design is still reviewed by a human before it goes into production.

How does Packative differentiate itself from traditional packaging companies and other packaging tech startups?

We started out by supporting small brands with very low MOQs, and we still do, but today we also scale to larger customers. What our customers value most is our speed. We achieve this because we constantly automate more and more processes in sales cycles and supply chain management, with automation and AI working heavily in the background. That is why we built our own ERP backbone—it gives us flexibility and full control over the heart of our operations. This allows us to be up to 600 times faster than traditional players, and even without owning a factory we can still deliver high quality at competitive prices with 15 suppliers in Korea. At the same time, we are investing heavily in research and innovation for AI, such as packaging design, to stay ahead and drive change not only in Korea but globally.

Could you share some milestones or achievements that you are most proud of since launching Packative?

Serving 3,500+ brands in Korea, one of the most competitive packaging markets in the world.

Producing more than 4.5M packages over the last four years.

Successfully closing a Pre-A Bridge Round in September 2025 led by Miraise (Japan), with Strong Ventures (US) and a strategic Japanese packaging company.

Becoming the first non-Korean founder to enter the TIPS program, breaking barriers for foreign-led startups in Korea.

Your platform integrates automation and real-time pricing—how did you design the technology stack to make that possible?

From the very beginning I approached Packative not as a packaging company but as a tech company. We are a tech startup. Yes, we sell packaging and we produce it, but the real value lies in the background: the supply chain, the speed we gain through technology, and the reduced resources needed to operate. That is why we built our own ERP backbone. It allows us to integrate real-time pricing by developing automated solutions that consider every possible production scenario, from different sizes to materials to printing methods. The result is that customers receive instant and accurate pricing, and we achieve operational efficiency at a level traditional companies cannot reach.

DYP.ai is positioned as a generative AI for packaging design. How does it work, and how is it different from general AI design tools?

DYP.ai is a generative AI tool we launched in April, built specifically for packaging design. Every design at Packative used to be checked manually by us and our factories to make sure it was print-ready. We turned that process into AI. With DYP.ai, brand owners or designers can generate a design with a prompt, directly on a diecut, and download a file already prepared for print production. We are now extending this to compliance and other steps in the design chain. In the future we imagine something even bigger: you create one design for a single packaging type, like a box, and AI automatically adapts it to all other formats you need—from tubes to tapes to labels. For companies managing thousands of SKUs, this will save enormous amounts of time and cost.

What are the biggest technical challenges in merging AI with packaging production workflows?

The biggest challenges are not only technical but also cultural. In production, digitization is still far behind. Fax is still a common medium for purchase orders, and many decision makers still believe packaging costs cannot be calculated automatically, even though we already have self-driving cars. On the design side, AI tools like Midjourney or ChatGPT have shown the creative potential, but production-ready packaging design is still at an early stage. That means adoption is slow and early adopters are rare. The challenge is to prove that AI can be trusted in environments where mistakes can cost millions, and to change mindsets in an industry that has resisted digital transformation for decades.

How large is the packaging industry opportunity you are targeting in Korea and globally?

The global packaging industry is already worth more than one trillion dollars and continues to grow steadily. The packaging printing segment alone is over 400 billion dollars today and is expected to surpass 600 billion by 2030. At the same time the ERP and workflow automation market is projected to exceed 170 billion by 2032, with AI adoption driving even faster growth. Packative sits right at the intersection of these markets. We are not only selling packaging but digitizing and automating the entire chain from design to production. That creates a multi-billion dollar opportunity far beyond packaging alone.

What lessons have you learned from scaling Packative from a startup idea to producing millions of packages?

I have learned so many things and I continue to learn every day. In the beginning I was much more of a perfectionist. I focused on pixel perfection and wanted everything to be perfectly planned and executed before launch. That mindset can kill ideas, startups, and progress. Over the years I have changed how I work. I now push for faster launches, test quickly, and improve in real time. Looking back, the last four years have not only given me gray hairs but also a lot of wisdom. There are things I could have done better, and I know I will do better in the future. Problems that used to bother me no longer do. Experience has taught me perspective, and that perspective is one of the most valuable lessons of all.

Sustainability is a hot topic in packaging. How is Packative addressing eco-friendly packaging needs?

Sustainability is a big focus for us, and we want to lead innovation in this space. But I also learned early on that because we do not own factories our influence on materials is limited. The reality is that only as we grow do we gain the leverage to demand broader use of sustainable materials. Over the last years we have already been promoting uncoated papers and recyclable packaging and actively pushing this forward. For us sustainability is not about attaching a label or marketing slogan. What matters is focusing on materials that truly stay in the cycle for decades, such as recyclable substrates and biodegradable plastics. That is the angle we believe will make a real difference over time.

Where do you see the biggest opportunities for Packative in the next 3–5 years?

In the next three to five years I want to see Packative established globally—not only as a marketplace or frontend for brands, but as the packaging operating system for the entire industry. Our goal is that Packative becomes the main brain for both sales teams and factories. Today we help brands design and order packaging faster, but in the future our platform will also control production itself, as software and data begin to drive physical attributes through physical AI. That is where the real transformation of the industry will happen, and Packative is building for that future.

What role do you envision AI playing in the packaging industry over the next decade?

Packaging is actually one of the least digitized industries in the world, only just ahead of gas and oil. It missed out on digital transformation over the last decades, which now creates a unique opportunity to skip steps. The companies that adopt early—from generative AI to agentic AI and eventually physical AI—will define the future of packaging. We already see great innovation in printing and some production areas, but many core processes like cutting or coatings are still based on old mechanical systems, and upgrading them is often unaffordable for large-scale factories. I believe physical AI, including humanoids, will change that completely. Imagine a highly customized order comes in over Packative. Our packaging OS agentically plans the best production steps, uses generative AI to fix design issues, and then works together with humanoids powered by AI to operate the machines. That will redefine what on-demand production means and open a new era of packaging.

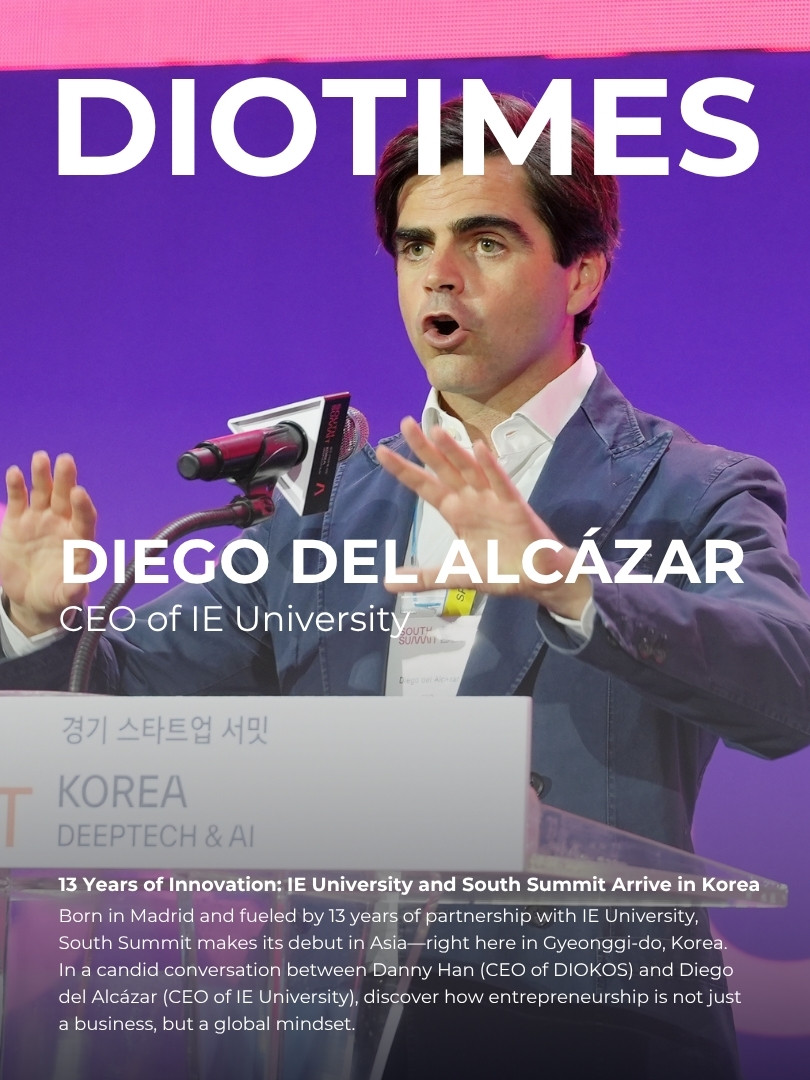

Why did you decide to participate in South Summit Korea 2025, and what are your goals for the event?

I am European by background and Korean by choice. Europe gave me my values, design mindset, and openness. Korea gave me speed, safety, and resilience. My dream is to see a Global Korea where borders disappear, where global talent feels welcome, and where expansion between continents is much easier. At the same time, I am proud European and want to see a united Europe that becomes the powerhouse it has the potential to be. South Summit Korea is one of the platforms to bring Europe and Asia closer together. For me it is a chance to showcase how foreign founders can thrive in Korea, to attract attention from both markets, and to build connections that can turn into investments and partnerships.

How do you see Packative’s role in connecting Korean innovation with the global startup ecosystem?

There is a reason why the American Dream was so powerful. In the US, 55 percent of billion-dollar companies were created by migrants. Globalization always starts in the country that truly wants to be global. If Korea wants to promote a Global Korea, it has to start by being global first—welcoming talent and creating opportunities not only for Koreans but also for foreign entrepreneurs. I see Packative’s role in this as twofold. First, to bring in talent and create an ecosystem where knowledge can be shared across cultures. Second, to become a role model that shows it is possible not only for a foreign founder to build a global company out of Korea but also that it’s possible to build a global company with a Korean HQ that can close investment from Europe, the US, and Asia.

What kind of partnerships or investors are you hoping to meet during South Summit?

I hope to have a good exchange with people at the event, not just to present Packative but to listen and learn as well. With investors I especially want to discuss what it will take to see more European capital flowing into Korea and also more Korean capital staying invested in Korea. For me the right partnerships are about building bridges. Capital is one part, but what matters just as much is opening the doors for long-term collaboration between markets.

What advice would you give to entrepreneurs trying to digitize traditional industries?

My main advice is resilience. The amount of bad things that happened while building this business would already have made many people give up. The resistance of the traditional industry, the cultural and language and tech understanding barriers, discrimination, lack of experience, not asking for help, hiring the wrong people … I could go on and on. You will meet decision makers who say things cannot be automated, suppliers who insist the old way is the only way, and customers who are afraid to take the first step. There is no single approach that works everywhere. Sometimes you need to prove value with speed, sometimes with cost savings, and sometimes with trust built over time. The key is not to give up when the resistance comes, because that resistance is part of the process of change.

Looking back, is there a defining risk or decision that significantly changed Packative’s growth trajectory?

There were two defining moments for me. The first was in 2020, when Packative was only an idea. I was working intensely on developing the company, living off my savings, and trying to renew my visa. Suddenly the immigration office accused me of running a shell company because I was not paying myself a salary. I was devastated and scared. Because of COVID the investigation dragged on for eight months. Investigators came to my office randomly, my visa officially expired, and after six months the banks suspended my accounts. I could not access company funds or even my personal accounts. It was one of the hardest times of my life and a moment that made me determined to help ensure other foreign founders would not have to face the same unnecessary barriers.

The second moment came six months after launching Packative. Everything seemed to crash at once and I was ready to give up. I called my first investor one month after we received the funds and explained the situation honestly. He listened and then said: “Dominik, it is up to you. The reason we invested in this company is because of you—only because of you.” That sentence gave me the conviction to continue. It reminded me that investors back founders, not just ideas. Without that moment I might not have pushed forward, and Packative would not be where it is today.